Custom 3D Printing & Design

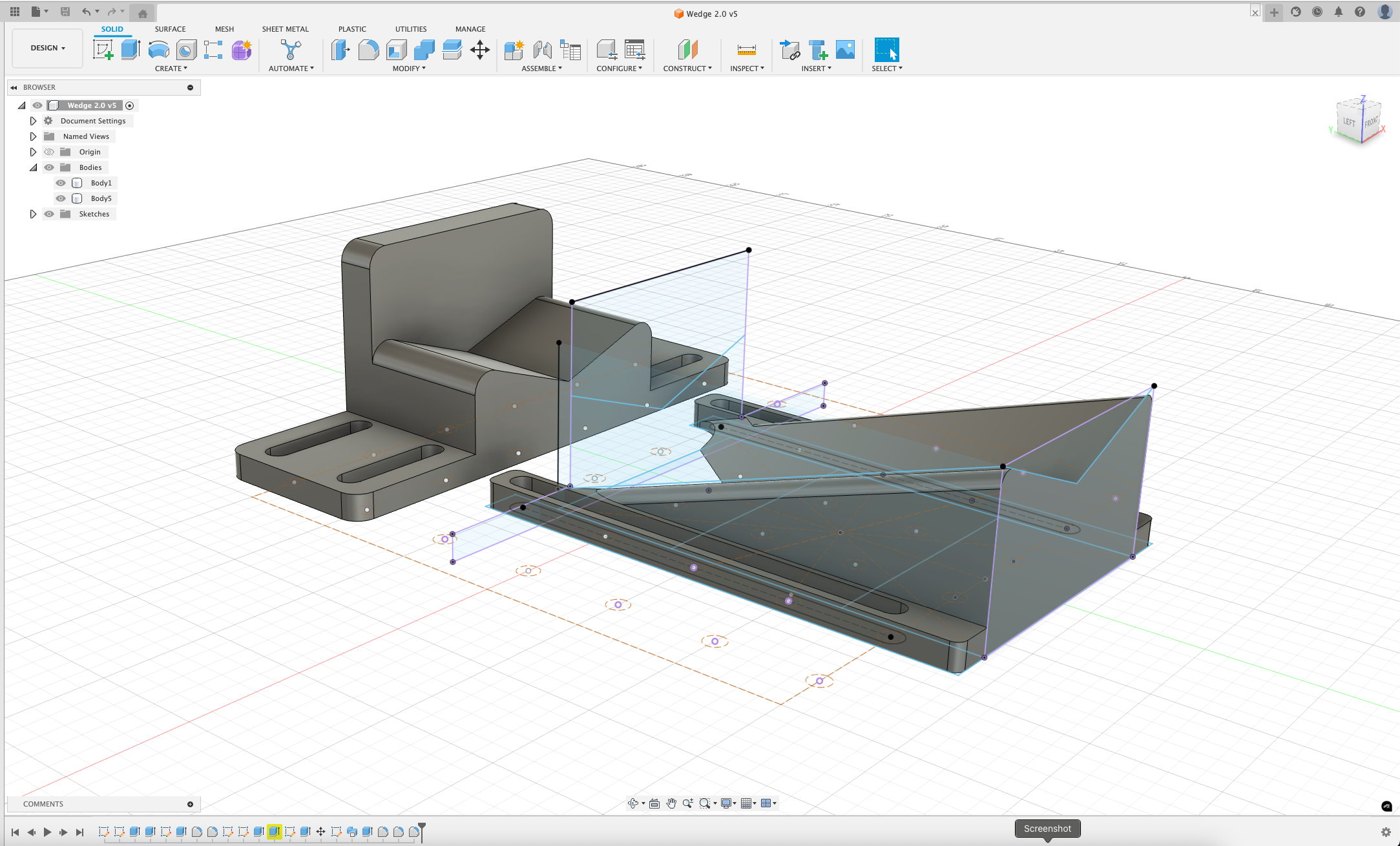

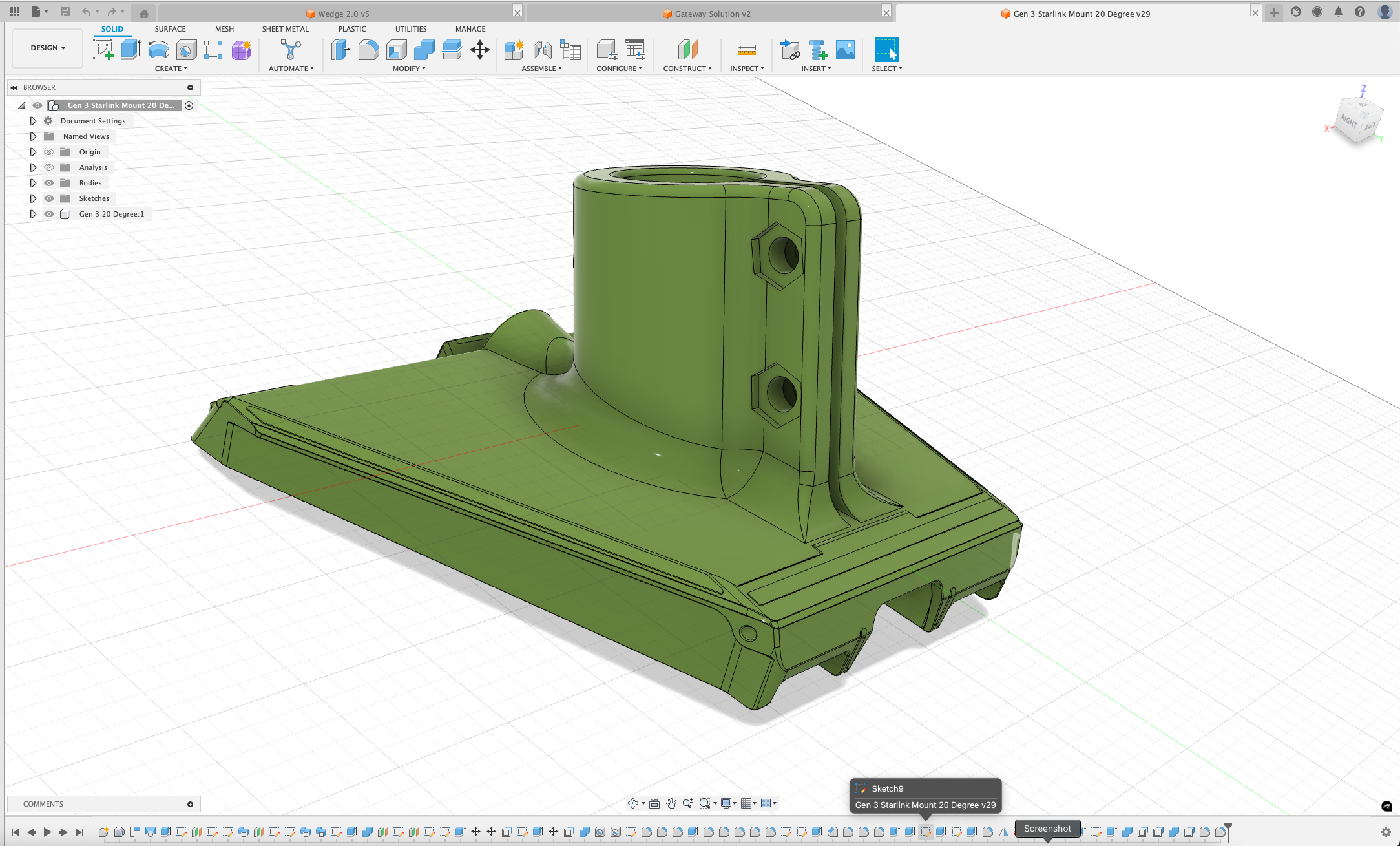

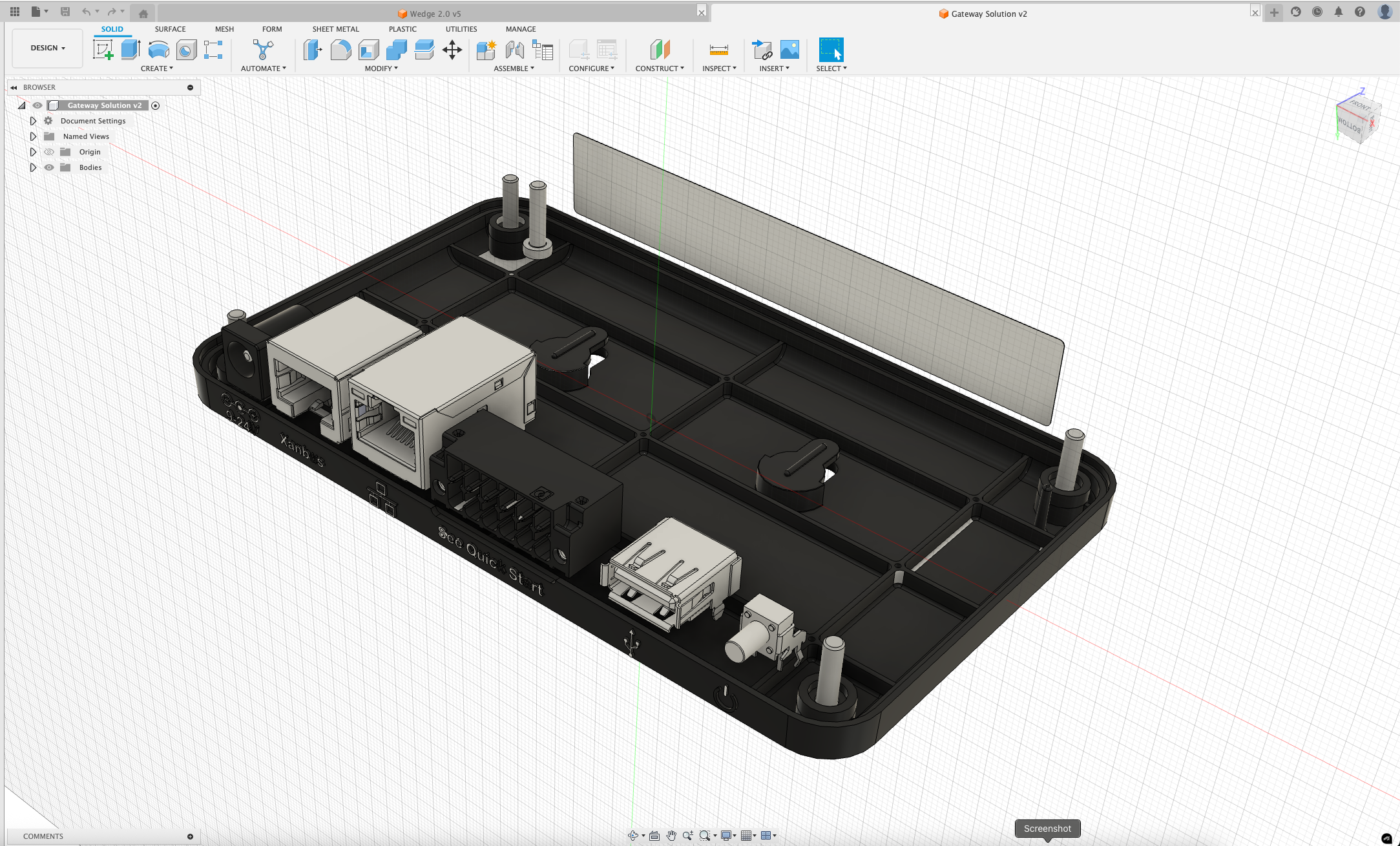

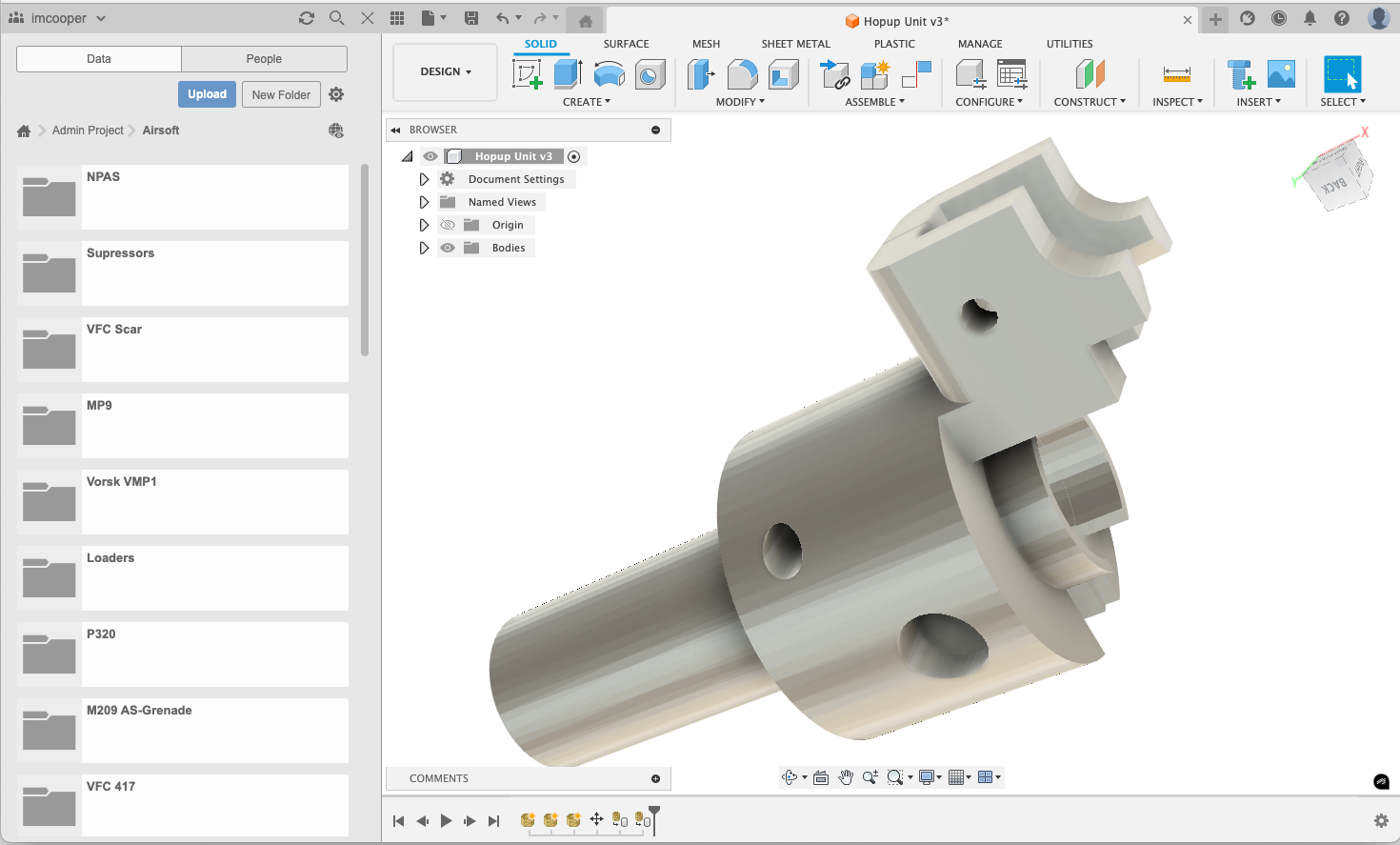

3D printing and design for additive manufacturing. I specialize in creating functional, optimized components tailored for 3D printing technologies, from prototyping to production. My experience spans CAD modeling, material selection, and designing for printability, strength, and efficiency. I combine engineering principles with cutting-edge digital fabrication to bring innovative solutions to life.

Using high-resolution printers and durable materials like PLA+, PETG, and High Temp Nylon blends, we can prototype, test, and produce parts quickly—often with faster turnaround than traditional machining or injection molding. This means we can help you bring custom ideas to life, from functional upgrades to aesthetic enhancements, with incredible detail and reliability.

Our Process

Custom CAD design based on your requirements

Rapid prototyping to test fit and function

Material selection for strength, flexibility, or lightweight builds

Fine-tuned prints for tight tolerances and consistent performance

Iterative Prototyping

We can share CAD files or screenshots, and I can provide feedback or help you:

Automate repetitive tasks using Fusion 360’s scripting.

Convert between file types or prepare for 3D printing (e.g., STL optimization)

"Printing for prototyping" is the skill of using 3D printing to create physical models of a design—typically during early stages of product development—to test form, fit, and function before moving to full-scale manufacturing. Here's a breakdown of what this skill includes:

Problem-Solving and Design Thinking

Our understanding of engineering principles means we can go beyond the basics and:

Collaborate on design for manufacturability (DFM)

Explore parametric modeling techniques together

Use Fusion’s cloud collaboration to co-develop projects more efficiently

If you're ever stuck, I can help with technical documentation, scripting, feature walkthroughs, or even generating model examples.